We supply Bracket/Hinge/Strap/Flange, select your favorite Marine Hardware/Tools/Bearing to send us an inquiry email or leave us a message, we will contact you within 24 hours, for your quotation.

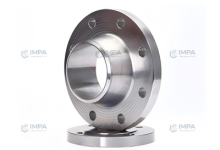

| Flange type | Sliding type; Welding neck, sleeve welding, blind hole, thread, splicing; Long welded neck; Hole Convex, planar and RTJ of all flanges; |

| Materials | ASTM A105; A350 LF2; A694 F42,F46,F52,F56,A182 F12 / F22 / F5 / F9 / F91; A182 F304 / F304L / F316 / F316L |

| Size | 1/2 “~60”, as the customer’s requirements; |

| Pressure | Classification:150 300 400 600 900 1500 2500; PN6,PN10,PN16,PN25,PN40,5K,10K,16K,20K,30K |

| Standard | ASME B16.5,ASME B16.47,MSS SP43,EN1092 ,DIN,JIS; |

- The price of a sliding flange or so flange is usually lower than that of a welded neck flange, so it is a popular choice for our customers. However, customers should keep in mind that the additional cost of properly installing the two angle welds required may reduce initial cost savings.

In addition, the sliding flange under pressure of the welded Farambi has a higher life expectancy. The sliding flange usually has a neck and has a straight hole, and the pipe will pass completely through. The installer slides the flange to the end of the pipe and locates the flange so that the angular weld between the neck and the pipe, as well as the Franconne angle weld between the end and the flange hole, will be fixed and sealed.

The connection to the pipe is done through 2 angular welds, also on the outer side and inside the flange. One drawback of flanges is that, in principle, pipes must always be welded first, and then welded. The combination of flange and elbow or flange and three-way is not possible because the named accessory does not have a straight end and completely slips into the sliding flange.

steellab

steellab