We supply Bracket/Hinge/Strap/Flange, select your favorite Marine Hardware/Tools/Bearing to send us an inquiry email or leave us a message, we will contact you within 24 hours, for your quotation.

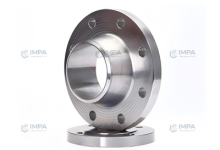

| Flange type | Sliding type; Welding neck, sleeve welding, blind hole, thread, splicing; Long welded neck; Hole Convex, planar and RTJ of all flanges; |

| Materials | ASTM A105; A350 LF2; A694 F42,F46,F52,F56,A182 F12 / F22 / F5 / F9 / F91; A182 F304 / F304L / F316 / F316L等 |

| Size | 1/2 “~60”, as the customer’s requirements; |

| Pressure | Classification:150 300 400 600 900 1500 2500; PN6,PN10,PN16,PN25,PN40,5K,10K,16K,20K,30K |

| Standard | ASME B16.5,ASME B16.47,MSS SP43,EN1092 ,DIN,JIS; |

- The threaded flange looks very similar to the sliding flange, but the main difference is that the threaded flange has been drilled to match the inner diameter of a particular pipe.

The rear side of the center opening is then tightened with the conical tube thread of the relevant size. Threaded flanges are used in special cases, the main advantage of which is that they can be connected to the pipe without welding.

Sometimes sealed welds are also used with threaded connections.

Although it is still available for most sizes and pressure levels, today’s threaded fittings are used almost only for smaller pipe sizes. Threaded flanges or fittings are not suitable for piping systems with thinner wall thickness, as it is not possible to cut threads on pipes. Therefore, a thicker wall thickness must be selected at least equal to ASME B36.10 schedule 80

steellab

steellab